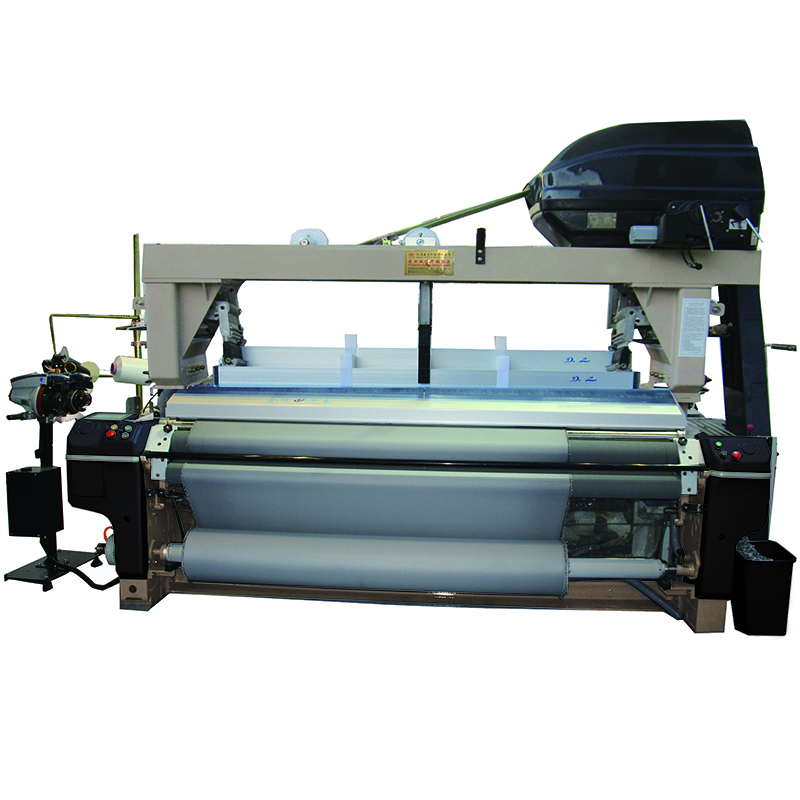

Factory directly supply 220 Air Jet Textile Machine - Staubli 1351 Cam Air Jet Loom – WINTOP

Factory directly supply 220 Air Jet Textile Machine - Staubli 1351 Cam Air Jet Loom – WINTOP Detail:

Video

Production Description

The reasonable beam structure,to further optimize the beam structure,the change of warp tension sensing more sensitive. After the tension roller bracket installed on the outer side of the frame,which is convenient for installation and maintenance.

This series of looms have the advantages of high rigid frame structure and so on. It is suitable for weaving high density and fine fabric.It also has the electronic control,which can effectively reduce the probability of weaving defects,such as stop gear,mechanical gear,broken warp,short weft and so on,and improve the weaving quality.

Main Feature

1. High Speed:New weft insertion,New frame structure and high speed CPU,ensure the running speed.

2. Low Energy Consumption:New weft insertion and main nozzle energy saving optimal design realize less air consumption.

3. Low Vibration:Using 3D design and computer analysis to optimize the frame structure,including the cross rail connection,and to realize Lightening design and optimum balance of the beating motion.

4. Flexibility and wide applicability:A full range of standard equipment and a variety of options can weave fabrics that were previously mostly woven by rapier looms,including wide home furnishing fabrics,stretch fabric,fabric of different yarn types and counts,airbags,seersucker and fabric with tuck in selvage.

5. Easy Operation and New Electronics:Relatively lower machine,Upper temple are both good for the operator;A new internet-ready color function panel with enhanced communication capability and a new,faster CPU.

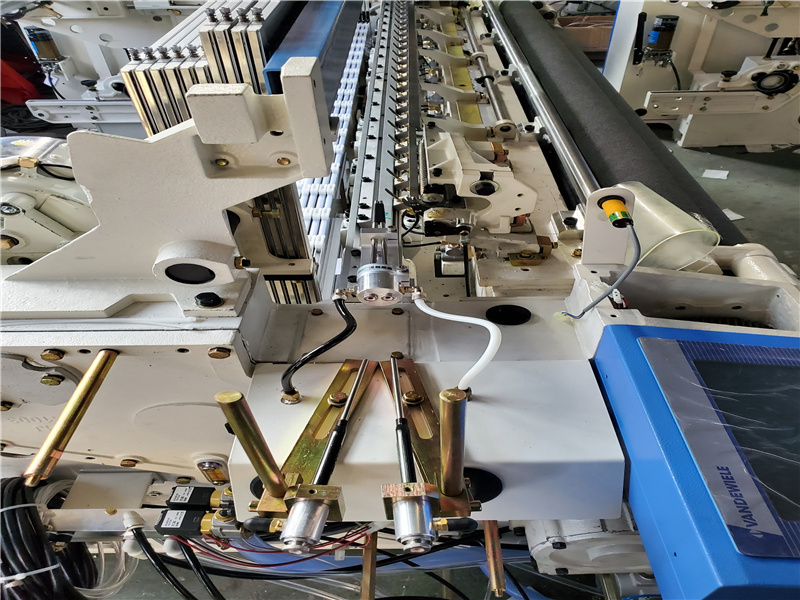

Product detail shows

Technical Specification

| Item | specification | Spare parts | |

|

Reed Width |

space(CM) |

150,170,190,210,230,260,280,300,320,340,360 | |

| Norminal R/S:0-60CM(150-250cm),0-80cm(>280cm) | |||

| Working Range | Short yarn.mel00-ne2.5 Filament:22dtex-1350dtex | ||

| Weft Selection | 1.2.4 or 6 color | ||

| Motor | Start Mode | Start motor at high speed | |

| Push-button start,stop,f/r slow move | |||

| Push-button switch handed | |||

| Power | 2.8Kw,3.0Kw,3.8Kw,4.5Kw | ||

| Weft Insertion | Method | Main nozzle+swing nozzle+sub nozzle + abnormity lock | Weft brake |

| Control | Import High-frequency solenoid valve,computer program control | ||

| supporting spray solenoid vavle | Supporting spray solenoid valve integrated with flow cavity | ||

| Measuring weft storage | Electric control loop separate weft storage | BallooningPreventionDevice | |

| Beating | Beating-UpMotion | Double side tank oil-bath type four-bar beating-up motion | |

| Multi-sleysword solid beating-up warp and weft system | |||

| Multi supporting base,balance weight | |||

| shedding | Crank type flat shedding(heald frame 4 to 8);1/1 fabric | ||

| Down positive Cam shedding(heald frame 4 to 14);Plain,twill,satin,black out fabric | |||

| Dobby shedding(heald frame 16 max);Plain,twill,satin or complex design | |||

| Electronic Jacquard shedding:1344,2688 lifting hooks | |||

| Let off | Electric servo continuous let-off | Double-warpbeam | |

| Twin back beam | |||

| Positive or negative let off | |||

| flang Dia | φ 8 0 0 m m | 中1000mm | |

| Take up | Batching Method | Mechanical continuous take-up | Electric servocontinuoustake-up |

| Batching Method | Entrails batching(Max diar1000mm) | ||

| Temple | Lower or upper | ||

| Selvage | Leno yarn by planetary gears | ||

| lubrication | For main driving parts:oil-bath type,centralized filling oil(grease) | ||

| Shutdowndevice | Weft breakage | Reflecting double feeler device | |

| Warp breakage | Electric warp stop device | ||

| others | Selvage,yarn end treatment, end-broken stop motion | ||

| Shutdowndisplay | Screen display,multi-functional shutdown display lights | ||

| Weft cutter | Mechanical cutter | ||

| Electriccontrolsystem | High deficiency,large screen,vga color image display touch human-computer interface | ||

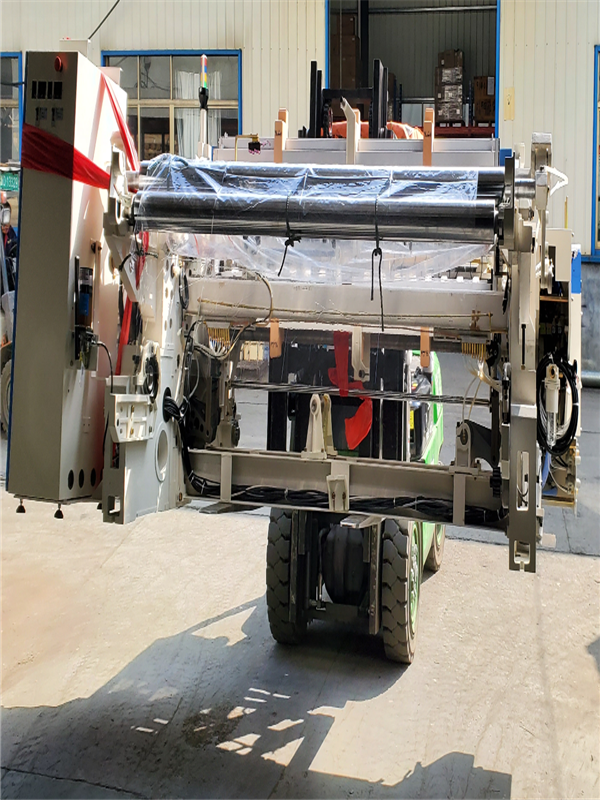

Delivery shows

Our customers come from all over the world, the main markets are in India, Indonesia, etc.

FAQ

What are your price?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Do you have a minimum order quantity?

The MOQ is 1 set, but usually we sell by the full container.

What about machine quality guarantee period?

Frames 1 year guarantee, easy damaged parts 3 months guarantee, and also we will give away free accessories according to the order quantity.

What terms of payment are acceptable to you?

You can make the payment to our bank account,usually 30% deposit and 70% payment before delivery by T/T.

Where is your factory located? How can l visit there?

Our factory is located in Jiaozhou, Qingdao city. You can fly directly to Qingdao airport. We warmly welcome all customers at home and abroad to visit and guide!

Product detail pictures:

Related Product Guide:

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Factory directly supply 220 Air Jet Textile Machine - Staubli 1351 Cam Air Jet Loom – WINTOP, The product will supply to all over the world, such as: New Zealand, Costa Rica, New Zealand, Insisting over the high-quality generation line management and prospects guide provider, we have made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!