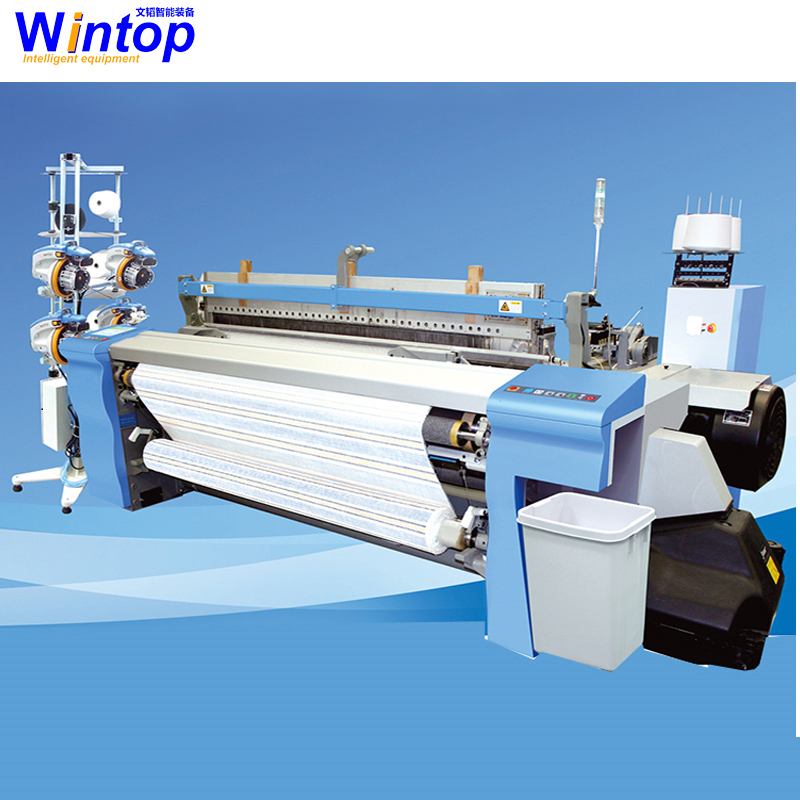

High Speed 150-360CM Plain/Cam/Dobby/Double Beam/Jacqard 2-8 Colors Heavy Air Jet Loom WA820

High speed

1)optimized frame structure achieves even lower vibration during high speed operation

2)well-balanced new beating motion

3)advanced high speed control system with multi CPU

Remarkable energy savings

1)the new completely weft insertion system features main nozzle,subnozzle,reed and more

2)Air pressure is reduced and a reduction in Air consumption is achieved

Intelligent& user friendly

1)A large function panels improves visibility and operability

2)Internet function and new communications technology realize highly intelligence

3)easily operate by workers due to ergonomics

Adopting by beating-up device, new-type wallboard structure, high speed with CPU processing, the running speed can reach 1250RPM.Electronic take up and electronic let off.Using four rod or six rod beating-up mechanisms to ensure enough beating time for weaving ,so as to give excellent weaving performance for WA820 air jet loom

The main nozzle, nozzle combined with high performance solenoid valves ensure excellent weft insertion performance.

Warp stop device can quickly find out the broken warp position, thereby improving the weaving efficiency.

Optional parts:Computerized control refueling device;Tuck in Device;Weft sensor; Middle cutter

Middle cutter:Meets the functional requirements of dual open width weaving machine,improve atuomatic level for weaving machine.

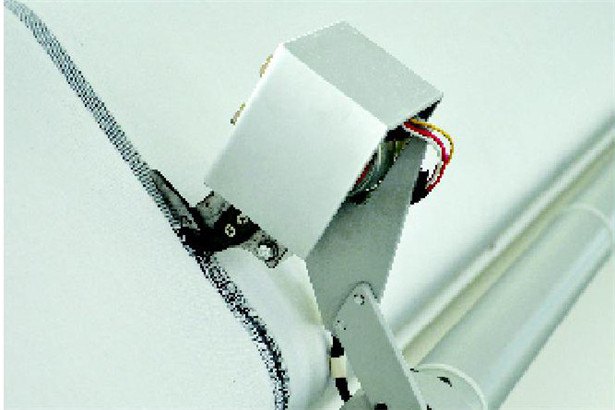

Electronic cutter:Simple and compact structure,convenient adjustment,high speed,efficient intelligent.

Weft senor:Single head chrome-plated weft sensor;Sensitivity can be set;Optocoupler Outout

| Standard Specifications of Air Jet Loom | ||

| 1 | General | |

| Model | WA820 high speed air jet loom | |

| Speed | 800-1000 Rpm depend on different yarn. | |

| Nominal reed space | 190cm-360cm | |

| Reduction reed space | Reduction reed space from nominal 0 to - 60cm | |

| Yarn range | Spun Ne 120 ~ Ne 30 | |

| Weft selection | 2-8 color pick at will | |

| 2 | Frame | Lower built, heavy duty frame. Main gears run in oil bath. |

| Loom raise-up by inclined base liner for larger loom beam diameter. | ||

| 3

|

Driving

|

Direct drive with high torque quick start motor. |

| Push button operation for Run in one side, Stop, Forward inching, and reverse inching from both sides. | ||

| (Run bottom operable only by both hands operation) | ||

| One step reverse revolution by one push button. | ||

| Fitted with quick start motor kw 410V 50Hz | ||

| One set of V-belt. | ||

| One piece of motor pulley. | ||

| quote separately inverter cost. | ||

| 4 | Shedding | Crank shedding, cam shedding, dobby shedding or Jacquard |

| 5

|

Let-off

|

ROJ |

| Fully automatic positive electric let-off system (ELO) with programmed kick-back function. | ||

| Peak tension compensation by positive easing motion with double roll system. | ||

| 6

|

Take-up

|

ROJ |

| Fully automatic positive electric take-up system. | ||

| Programmable pick density setting through touch screen. | ||

| On loom take up and maximum roll diameter 600mm. | ||