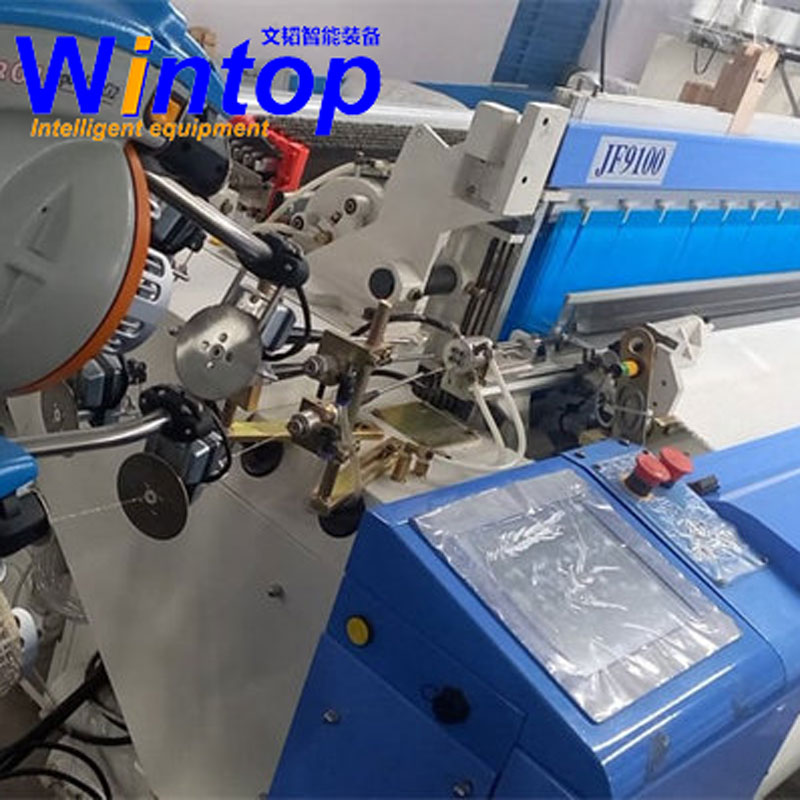

Staubli 2678 Dobby Air Jet Loom-190cm 4nozzle

High Speed

New weft insertion,New frame structure and high speed CPU,ensure the running speed max.1200RPM

Low Energy Consumption

New weft insertion and main nozzle energy saving optimal design realize less air consumption.

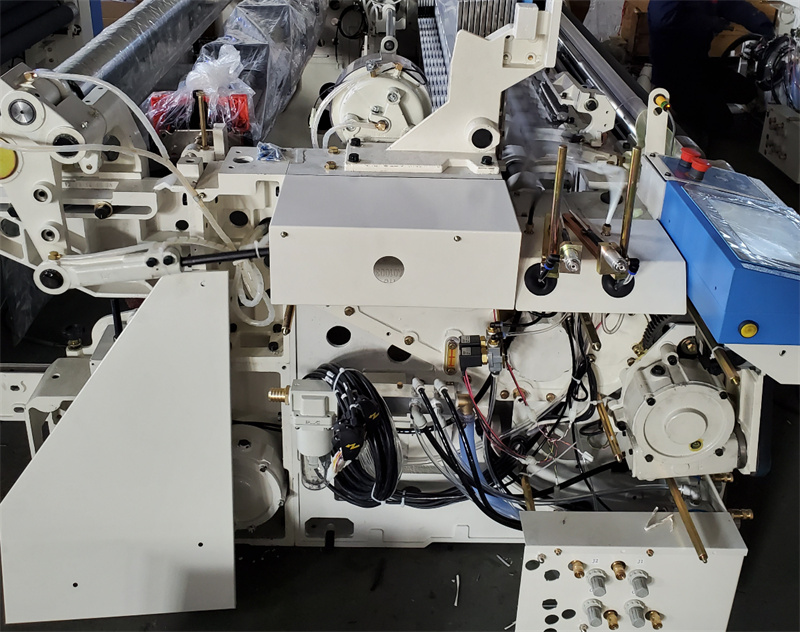

Low Vibration

Using 3D design and computer analysis to optimize the frame structure,including the cross rail connection,and to realize Lightening design and optimum balance of the beating motion.These improvements ensure lower vibration with high speed operation

Flexibility and wide applicability

A full range of standard equipment and a variety of options can weave fabrics that were previously mostly woven by rapier looms,including wide home furnishing fabrics,stretch fabric,fabric of different yarn types and counts,airbags,seersucker and fabric with tuck in selvage.

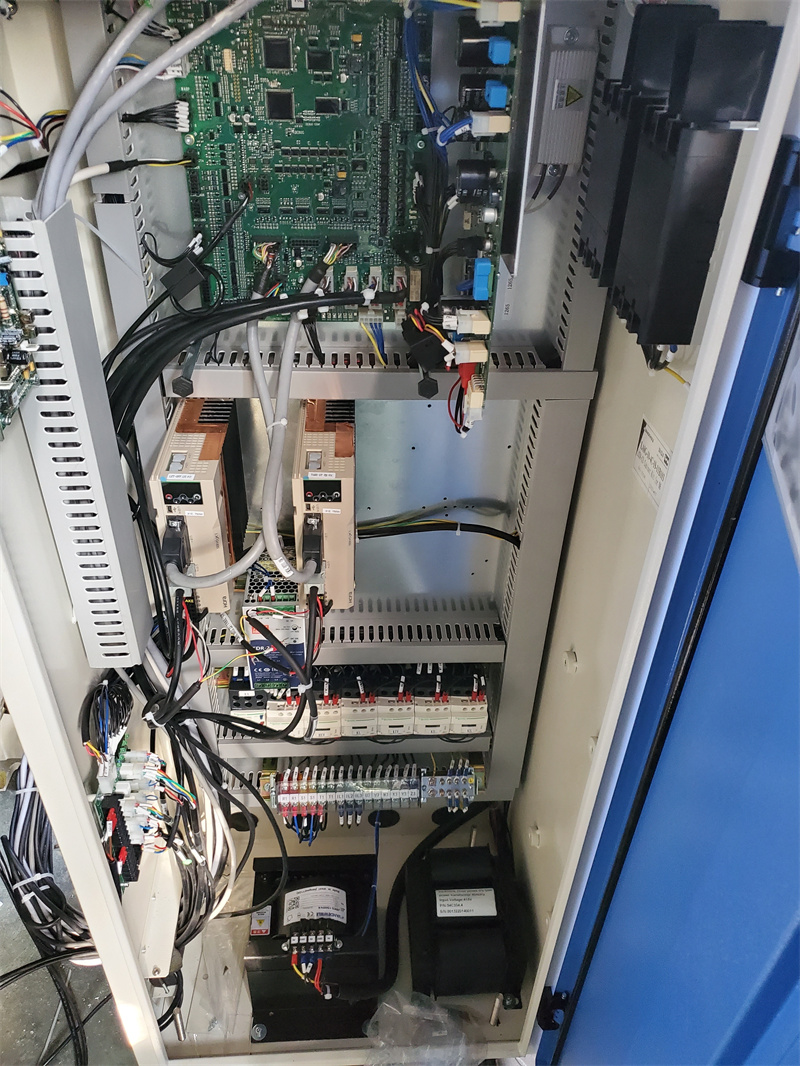

Easy Operation and New Electronics

Relatively lower machine,Upper temple are both good for the operator;A new internet-ready color function panel with enhanced communication capability and a new,faster CPU.

| Item | specification | Spare parts | |

|

Reed Width |

space(CM) |

150,170,190,210,230,260,280,300,320,340,360 | |

| Norminal R/S:0-60CM(150-250cm),0-80cm(>280cm) | |||

| Working Range | Short yarn.mel00-ne2.5 Filament:22dtex-1350dtex | ||

| Weft Selection | 1.2.4 or 6 color | ||

| Motor | Start Mode | Start motor at high speed | |

| Push-button start,stop,f/r slow move | |||

| Push-button switch handed | |||

| Power | 2.8Kw,3.0Kw,3.8Kw,4.5Kw | ||

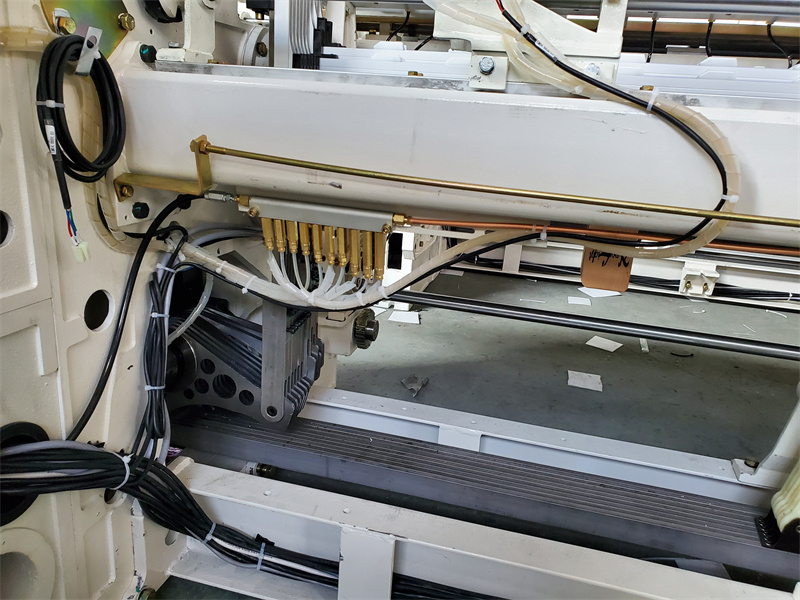

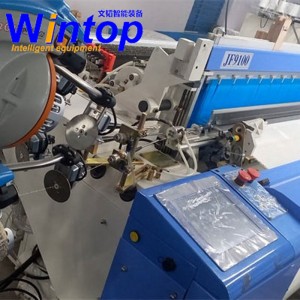

| Weft Insertion | Method | Main nozzle+swing nozzle+sub nozzle + abnormity lock | Weft brake |

| Control | Import High-frequency solenoid valve,computer program control | ||

| supporting spray solenoid vavle | Supporting spray solenoid valve integrated with flow cavity | ||

| Measuring weft storage | Electric control loop separate weft storage | BallooningPreventionDevice | |

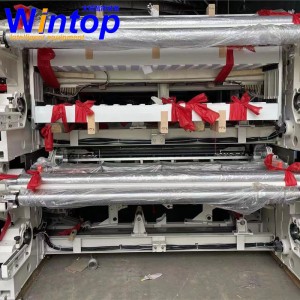

| Beating | Beating-UpMotion | Double side tank oil-bath type four-bar beating-up motion | |

| Multi-sleysword solid beating-up warp and weft system | |||

| Multi supporting base,balance weight | |||

| shedding | Crank type flat shedding(heald frame 4 to 8);1/1 fabric | ||

| Down positive Cam shedding(heald frame 4 to 14);Plain,twill,satin,black out fabric | |||

| Dobby shedding(heald frame 16 max);Plain,twill,satin or complex design | |||

| Electronic Jacquard shedding:1344,2688 lifting hooks | |||

| Let off | Electric servo continuous let-off | Double-warpbeam | |

| Twin back beam | |||

| Positive or negative let off | |||

| flang Dia | φ 8 0 0 m m | 中1000mm | |

| Take up | Batching Method | Mechanical continuous take-up | Electric servocontinuoustake-up |

| Batching Method | Entrails batching(Max diar1000mm) | ||

| Temple | Lower or upper | ||

| Selvage | Leno yarn by planetary gears | ||

| lubrication | For main driving parts:oil-bath type,centralized filling oil(grease) | ||

| Shutdowndevice | Weft breakage | Reflecting double feeler device | |

| Warp breakage | Electric warp stop device | ||

| others | Selvage,yarn end treatment, end-broken stop motion | ||

| Shutdowndisplay | Screen display,multi-functional shutdown display lights | ||

| Weft cutter | Mechanical cutter | ||

| Electriccontrolsystem | High deficiency,large screen,vga color image display touch human-computer interface | ||