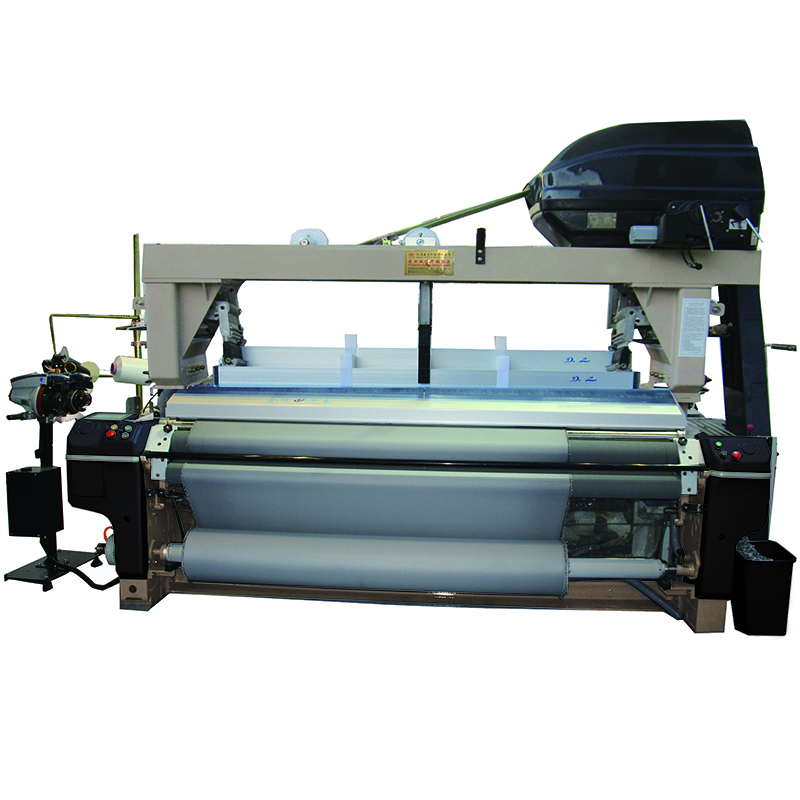

WT508H Twin Pump ELO&ETU 2-8 COLORS Off-set Shaft Heavy High Density Weaving Water Jet Loom

Weft Insertion Methodically At High Speed

The weft insertion angle is enlarged by improvement in the beating curve that ensure weft insertion stably for all kinds of chemical fiber materials,as the great improvement of unstable situation of shedding and warp yarn tension ensure weaving the differentiation fabric with high quality.

Stable Running

The robust frame structure,rigid let off and take up stabilize the loom running and the weaving range is increased from thin to middle-thick fabrics,and from low to high density fabric,even weave fabrics of complicated or unbalanced construction,vibration.

Crossing Stay

The front stay is rectangle, which width reach 200mm. The back top stay and both bottom stay are pentagon, which are strengthened for stable operation at high speed and high rigidity of beams is efficient to reduce resonance marks.

More Rigid

A transverse rail is employed to increase rigidity( for width more than 280cm loom, one extra or two extra is available)

New Design

Our new designed rocking shaft with small inertia moment is employed to attain well-balanced beating even at high speed.Comparing with other hollow rocking shaft, it reduce 25% of floor vibration.stable operation is possible at high speed.

1)Mechanical let-off and take-up;Electronic let-off and take-up.

2)RDP mechanical measuring&storage device,1-6 nozzle electronic weft selection freely.

Configurable shedding device:Niupai cam/Niupai dobby/jacquard

3)Reed width:135-450cm

4)The weft density range:4-100picks/cm(Identified according to actual weft yarn specifications and fabric weaving)

5)Max.speed:1000RPM(Identified according to actual weft yarn specifications and fabric weaving)

Heald frame :crank shedding 2-8pcs;cam shedding 2-14pcs;dobby shedding16pcs

Install power:2.8kw-5.4kw

| Type | WT406 | WT508 | WT8200 | |

| Reed Space(CM) | 135,150,170,190,210,230,260,280,300,320,340,350,360 | |||

| Useful reed space(CM) | Norminal R/S minus 2cm to 50cm | |||

| Frame | Box frame type Driving section is in oil bath | |||

| Driving | Brake | Direct stop mechanism by an electromagnetic brake | ||

| Controller | Push and touch button(Arrange,stop,forward,brake,reverse) | |||

| Motor | Rush start motor | |||

| Motor power | 1.5kw,1.8kw,2.2kw,2.7kw,3.2kw,3.7kw,4.5kw,5.4kw | |||

| Beating | Crank beating | |||

| Let off | system | Automatic mechanical and continuous let-off;Or electronic let-off,One or vertical two roll | ||

| warp beam | Φ800mm flange,Φ178mm barrel | |||

| Take up | system | Mechanical or electronic continuous take-up | ||

| Pick density | Normal:5-60picks/cm;Special:4-100picks/cm | |||

| Cloth wind-up diameter | Φ420mm,Φ520mm,Φ600mm | |||

| Shedding | Plain shedding | crank shedding(heald frame 2 to 8;1/1 fabric | ||

| Cam shedding | Cam shedding(heald frame 2 to 14);Plain,twill,satin babric | |||

| Dobby shedding | Positive/negative(heald frame 16 max.);Electronic and mechanical reading system;Plain,twill,sation or complex design | |||

| Jaquard | 1408,2688,5120 lifting hooks;electronic jacquard device | |||

| Weft insertion | Measuring and storage | 300#RDP type mechanical measuring turbo blower(single nozzle)Or electronic weft feeder(1-6nozzles) | ||

| Pump | M,L,H type, Single or Double | |||

| Plunger | Ceramic plunger;Φ32/Φ17,Φ32/Φ18,Φ32/Φ20,Φ36/Φ22,Φ36/Φ24,Φ36/Φ26,Φ39/Φ26,Φ39/Φ28,Φ39/Φ30,Φ50/Φ35 | |||

| Nozzle needle | ST20/10;ST30/10;ST45/20,SD75/40 | |||

| Weft filling | 1/2/3/4/6 nozzle | |||

| Filling feeder | Electronic,optical,and self-control | |||

| Selvage/Leno system | Twisting by star,planetary gears | |||

| Electrical part | Madeinchina/import | Main control board,AC contactor,transformer,NC interface,Selvagebrake system,Waste yarn brake system,overheating and overload protection | ||

| Electronic meter | count and display,rotational speed,total yield,team yield,total efficiency,team efficiency,cloth length auto control,stopping analysis and display | |||

| Other devices | take up roller-one;weft density gear-one;Trashcan-one;nozzle needle-one set | |||